A simplified explanation of footwear construction:

- After the upper has been sewn (it often looks like a hat worn by poker dealers - with a bill & a strap in the back) the shoe is finished by placing the upper around the last, pulling it with pliers until it's tight, hammering tacks into the last to hold it in place (that's why lasts are wood) and then hammering the upper until it conforms to the shape of the last.

- The bottom edges of the shoe are then trimmed (and for welted footwear, the welt is sewn on) and the sole is glued and sewn to the upper.

- After the glue dries, the last is then pulled out so the footbed (or insole) can be inserted.

- No matter what fancy designs you make on the upper, the last determines how good or bad a shoe will look, much the same way clothes fit... if they are shaped strangely, it doesn't matter what color or material your shirt or pants are, they will still just look terrible. And if you have an ugly last, the shoe can be made of the finest materials and fanciest design and still be ugly!

Did you know?

About re-dyeing shoes

Your local cobbler can dye existing shoes any color you wish. The process that's used when done properly is to strip the existing color off with acid - right down to the grey leather, then apply the color you want. After it's shined up, it is virtually impossible to tell that the new color wasn't the original. We have seen this done to a black pair of captoes that the owner wanted to change to white. If you'd like to waste an afternoon and ruin your shoes just buy a bottle of shoe dye and apply it to your shoes so the color can crack off when you walk in them.

About stretching shoes

Shoes can be stretched by a cobbler who inserts a shoe stretcher into the shoe, moistens the upper, and turns a screw which opens the stretcher to widen the shoe. It is stretched for a period between a few minutes to overnight. Back in the day it was expected that one would have to "wear in" their brand new shoes. Modern shoes have almost no break-in period, but, it could be argued, a shorter expected lifespan because of this.

About Shoe Sizing

Why doesn't everybody know their exact shoe size?

First, because there is no standard global system - you can wear one "size" in Europe, a different one in Australia, in Asia, the U.S. and England. Second, because of a practice as old as the village shoemaker and his own personal size numbering system, big companies today (mostly athletic footwear manufacturers) will inspire customer loyalty by making sure their sizing system doesn't exactly match anyone else's sizing ("Wow - I never fit Nikes! But I always fit Adiddas. I wonder why?"). Aris Allen is not so proprietary! They strive to make sure their sizing matches closely to the sizing system employed by the big dress shoe manufacturers who make sure you fit the same size in any style in their line as well as when you cross over to a different brand. To test this theory: go into a Nordstroms or Saks and try on 5 different brands of dress Oxfords all in the same size. Then try the same thing at an athletic footwear shop. You'll be surprised.

Straight-Soled Shoes

Before the Middle Ages, shoemakers made individual lasts for the left and right foot. During the Middle Ages, this practice was lost and most shoes weren't even made on a last. If a last was used it was usually the same one for both the left and right shoes. In the middle of the 1800's the asymmetrical last regained favor and shoes fit much better than before. Much like many advances that are made in medicine, the asymmetrical shape coming back into vogue had to do with war. Apparently there was so much marching during the American Civil War (1861-1865) that straight soles were abandoned because breaking them in was uncomfortable and could cause blisters. Not such a problem when you're living at home and can change in to your slippers - but when out in the elements, fighting a war, marching to either evade or keep up with your adversaries; blisters and marching slower due to pain could be a life-threatening problem.

About the difference between Shoemakers & Cobblers

Shoemakers make shoes, Cobblers fix them.

About "Chrome Leather" - Chromium vs. Vegetable Tanned Leather

Vegetable Tanning - used for jackets, pants, and the uppers of shoes:

Leather can be preserved by tanning using tannins found in oak, spruce, mimosa, mangrove or acorns which makes it yellowish or beige in color.

Chromium Tanning - used for the soles of dance shoes, leather car seats, furniture:

Leather can also be tanned with Chromium Salts, hence the term for suede adhered to the bottom of dance shoes: "Chrome Leather" or "Chromed" shoes. This gives the leather a distinctive greyish-blue look. Another term for this is "Wet-Blue".

The soles and lining of most leather shoes are made with Vegetable Tanned Leather, but the bottoms of most dance shoes are covered with Chrome Leather Suede. This makes the suede bottoms more durable and allows them to be brushed clean so they grip the floor better (but don't do this for swing dancing!!). Aris Allens are made for the rigors and zippy moves of swing dancing so they are either soled with hard leather or Chrome Leather Suede. The latter functions similar to hard leather because it holds a shine beautifully which makes it easier to spin on and protects your knees in the process. For swing dancing they are not supposed to be brushed (like ballroom dancers do) and should be allowed to build up a mirror-like finish on the bottom.

Shoes that barely grip the floor are part of why the good dancers you watch have that "how do they do that - it looks like they're dancing on clouds" look that we all strive for. You will never get that wearing cross-trainers.

|

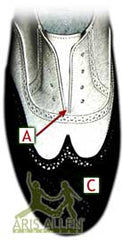

A Balmoral (or "Bal") refers to the way an Oxford style shoe ties up. See the little upside-down T pic? The horizontal line on the T is a good representation of the way a Balmoral is sewn at the bottom of the lace-up area. See [A] in the photo to the right. A Bal is far less adjustable than a Blucher because the bottom of the lace-up part of the shoe is sewn down, so the part of the shoe around the ball of the foot can only be one circumference and cannot be adjusted smaller or larger. Because of the lesser adjustability of a Bal, it is not as easy to fit people with narrow or wide feet. When properly tied, only the tip of the shoe's tongue can be seen. "Balmoral" refers to the castle in England of the same name and comes from Prince Albert taking an extended holiday at the castle in the mid 1800's while wearing a pair of boots made for him that had this type of construction for the lacing.

A Balmoral (or "Bal") refers to the way an Oxford style shoe ties up. See the little upside-down T pic? The horizontal line on the T is a good representation of the way a Balmoral is sewn at the bottom of the lace-up area. See [A] in the photo to the right. A Bal is far less adjustable than a Blucher because the bottom of the lace-up part of the shoe is sewn down, so the part of the shoe around the ball of the foot can only be one circumference and cannot be adjusted smaller or larger. Because of the lesser adjustability of a Bal, it is not as easy to fit people with narrow or wide feet. When properly tied, only the tip of the shoe's tongue can be seen. "Balmoral" refers to the castle in England of the same name and comes from Prince Albert taking an extended holiday at the castle in the mid 1800's while wearing a pair of boots made for him that had this type of construction for the lacing.

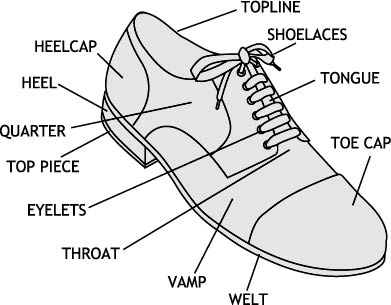

A Blucher, also known as a Derby, refers to a shoe with "open lacing". See the little brackets pic? That is a good representation of the way Blucher acts. It is far more adjustable than a Balmoral because the bottom of the fly (where the eyelets are) is not sewn down, so it can be pulled tight or allowed to be more open in the area around the ball of the foot. See [B] in the photo. Because of the greater adjustability of a Blucher, it is much easier to fit people with narrow or wide feet than a Balmoral will be. The tongue on a Blucher is usually just an extension of the vamp of the shoe. The vamp is the part of the shoe directly over the ball of the foot. (see Derby below). Named after Prussian field marshal Gebhard Leberecht von Blücher, Duke of Wahlstadt (1742-1819) who ordered these for his soldiers (he fought against Napoleon at the battle of Waterloo).

A Blucher, also known as a Derby, refers to a shoe with "open lacing". See the little brackets pic? That is a good representation of the way Blucher acts. It is far more adjustable than a Balmoral because the bottom of the fly (where the eyelets are) is not sewn down, so it can be pulled tight or allowed to be more open in the area around the ball of the foot. See [B] in the photo. Because of the greater adjustability of a Blucher, it is much easier to fit people with narrow or wide feet than a Balmoral will be. The tongue on a Blucher is usually just an extension of the vamp of the shoe. The vamp is the part of the shoe directly over the ball of the foot. (see Derby below). Named after Prussian field marshal Gebhard Leberecht von Blücher, Duke of Wahlstadt (1742-1819) who ordered these for his soldiers (he fought against Napoleon at the battle of Waterloo).